Ep.5: The pick and place assembly process

On this week's episode we talk about the pick and place assembly process (which also served as the inspiration for our show name) - the process of placing parts onto circuit boards using automated machines.

-We recap on how we've been adjusting in the factory amidst the continuing pandemic and how we're dealing with some of the growing pains as business starts to boom again.

-We discuss the steps after the parts are kitted that have to be done to get the board ready to be assembled:

The parts have to be loaded onto a feeder.

Loading an 8mm MyData feeder https://youtu.be/HU88ym0sdEQ

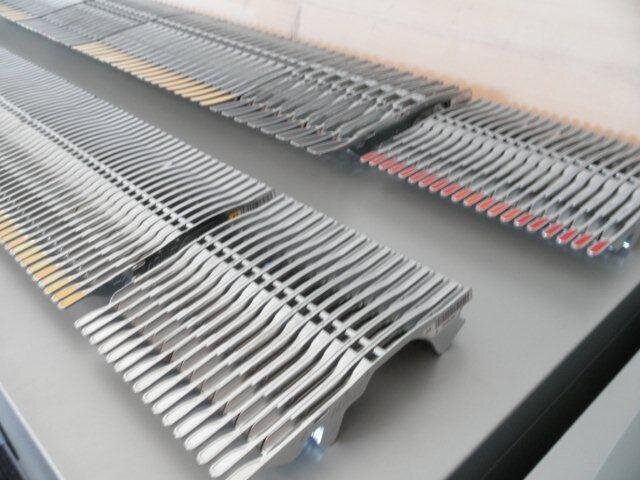

The feeders are placed in a magazine.

Mycronic feeders

Magazine

We briefly discuss the different types of feeders and magazines that are available.

On the Mycronic machines we use, the magazine is what advances the part in the pick and place machine.

MyData magazine advancement mechanism https://youtu.be/5ytCNuvdB2w

-We touch on the environmental impact of different types of equipment.

-Aside from tape and reel some parts come in tubes are trays and need to be loaded differently.

Mycronic stick feeder

-Why is set up one of the most time consuming steps in the whole manufacturing process?

-Once the parts are all loaded on to the machine, we describe the steps that have to be done in order to get it ready to run.

-We talk about the different types tools that are used to pick parts up and place them on the board and the technology that is used to make sure parts are being placed precisely and accurately.

-MyData machine in action https://youtu.be/B_bllEK55JU

-"Chip shooter" style pick and place machine: https://www.youtube.com/watch?v=nah4BQ9y8IY

-"Odd form" style pick and place machine: https://www.youtube.com/watch?v=EUxBMUS45Kg

-We talk things customers can do (and things we would prefer you to avoid) in order to make the pick and place process run smoother.

-On the next episode: We'll be speaking to Dugan and Nadim about their involvement with the Open Source Ventilator project.