Ep.20: How Blue Robotics is enabling the next generation of ocean exploration robots w/ Rustom Jehangir

What does a NASA JPL underwater vehicle that monitors methane bubbles in the arctic, robots that kill invasive species of starfish, and a robotics swan light show have in common? They are all examples that have used marine robotics components created by Blue Robotics.

We're so excited to have CircuitHub customer, Rusty Jehangir, on the show. He shares his story of how an idea to send a solar powered robotic surfboard from Los Angeles to Hawaii transformed into a company that provides the world's most affordable high-performance ROV and marine robotics components.

Learn more about Blue Robotics.

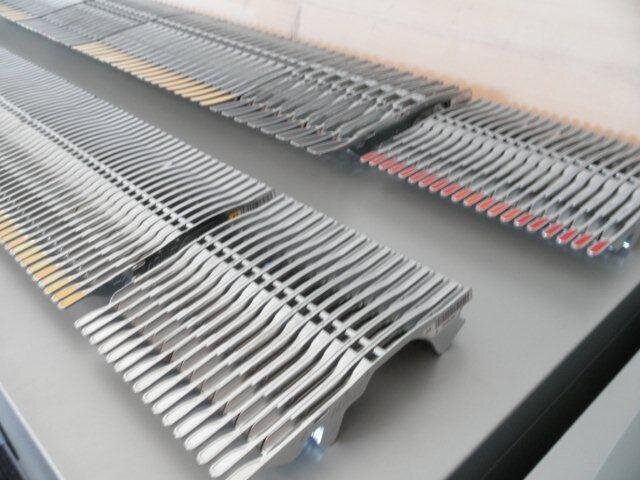

Ep.19: PCB Depaneling

PCB Depaneling is the process of breaking the individual PCBs out of the panel that is used to assemble the boards and is typically one of the very last steps assembled circuit boards go through before they are shipped.

Show Notes:

First, what are panels and why do we use them?

What factors dictate which panelization and breakout method is used?

What types of depaneling methods can be used?

What else happens during this step?

Guide to V-Scoring

Recommendations:

Consider how your product fits into its final location. Are there areas that must be dimensionally accurate?

Consider using recessed tabs (mouse-bites)

Ep.18: How sensors.AFRICA empowers citizens to fight against pollution w/ Jack McLeans

Everyone deserves to live in an environment free of pollutants. This is something that today's guest is especially passionate about.

On this episode we're joined by Jack McLeans to discuss sensors.AFRICA, a pan-African citizen science initiative that uses low-cost sensors to monitor air, water and sound pollution to give citizens actionable information about their cities.

sensors.AFRICA is a project under Code for Africa, which is Africa’s Largest Civic Technology + Open Data + Data Journalism Initiative. The initiative is open source; if you're interested in learning more or contributing check out their GitHub page.

Ep.17: Bare PCB Materials w/ Dave Wilcox

In this episode Dave Wilcox, CAM engineer at CircuitHub, joins us again to educate us on bare printed circuit board materials....think prepreg, laminate etc.

Show Notes:

-FR4 is the most common, widely available PCB material. It is a woven glass cloth filled with epoxy resin the is bonded together to form sheets of prepreg and laminate

-If a circuit board were a sandwich, the laminate is the bread and the prepreg is the filling.

-We discuss differences in FR4 used for lead vs lead free process.

-What does high TG and the different TG ratings mean?

-We briefly touch on some more exotic materials.

-The laminate comes in different thicknesses laminated with different copper weights that are used to build different stackups.

-Copper foil is used on the outside and also come in different weights.

-What does is mean to be UL approved and how to PCB fabs get UL approval?

-Sometimes more sheets of prepreg are used to get greater resin content.

-How do the different materials arrive at the PCB fab?

-Pet peeves - the news and printers.

Ep.16: The selective soldering process

On today's episode we continue on with our technical sub-series about the assembly process. We delve into selective soldering, which is used to solder through hold components onto boards.

Show notes:

-We answer a question from a listener about tomb stoning, why it is no longer as prevalent in pcb assembly today, and how to prevent it

-https://www.worthingtonassembly.com/perfect-0201-footprint

-https://www.worthingtonassembly.com/perfect-0402-footprint

-Worthington uses selective soldering machines made by RPS Automation which is now ---Hentec Industries - https://rpsautomation.com/vector460/

-Need to see it to understand it. https://youtu.be/p-VImd2yW5s

-Stages of selective soldering - we use 1. preheat 2. flux 3. solder

-Advantages vs disadvantages of selective soldering

-Design tips to make it go more smoothly

Ep. 15: The importance of having different perspectives in engineering w/ Eli Hughes of Tzero Labs (Part 2)

Welcome to the new year!

This episode is a continuation of our conversation with Eli Hughes of Tzero. If you haven't checked out the first part, we recommend you do so first before listening to this episode.

Show notes:

-Without first building relationships, trust can't be established.

-Even though engineers are dealing with highly technical problems, most have underpinning problems that aren't technical in nature.

-Eli's episode on the Amp Hour.

-Opinion: American chocolate is so much better than European/International chocolate.

-Pet peeve: Fans saying that "we won" the game.

-The importance of having diversity in gaining different perspectives.

-Are women better at assembling circuit boards?

-This is the best USB-C port.

-Eli's contact info: Twitter - @emh203 / Email: eli.hughes@tzerolabs.com

Ep. 14: How to build and manage a great team w/ Eli Hughes of Tzero Labs

On this episode, we chat with CircuitHub customer, Eli Hughes. He tells about how his work at the Penn State Applied Research Lab and background in acoustics led to the founding of Tzero Labs.

We also have a great conversation with him about the importance of building strong relationships with both your teammates and suppliers. The trust that comes out of it will ultimately help everyone work through the mistakes that inevitably pop up during the manufacturing process.

Show notes:

-Chris discusses a unique, recent situation where Worthington was having difficulty placing a part even though the customer did everything correctly in designing their footprint.

-We're talking to Eli Hughes, co-founder of Tzero Labs, which makes a real time fermentation monitoring system.

-Eli talks about his perspective, as an engineer, of what happens when things in manufacturing go wrong and how he's tries to prevent those errors.

-Eli: "While technical skills are important, understanding how to interact with other humans to build truly great organizations is the #1 key to success. Communication, curiosity and culture are of upmost importance in today's organizations. Get those three things right and groups of ordinary people can do extraordinary things."

-When you build a relationship with people, the fact that you made a mistake isn't what you're worried about.

-Founders of Tzero Labs came out of the Pennsylvania State Applied Research Laboratory (ARL) which is a U.S. Navy University Affiliated Research Center.

-Eli discusses the story behind Tzero Labs was formed and what exactly their product does.

-We touch on the importance of building trust in your business relationships.

We had such a great time chatting with Eli that we ended up with nearly 3 hours of recording. The second half of our conversation will be coming out in the new year.

Thank you to each and every one of you who tune into our show. It truly puts a smile on our face when we hear you tell us you've been enjoying it. We have a ton of content to talk about in 2021 and we can't wait!

We hope everyone has a wonderful and safe holiday season!

-Melissa and Chris

Ep.13: Automated Optical Inspection (AOI) for PCB Assembly

In this episode we delve into the process of Automated Optical Inspection (AOI). We cover what details of the circuit board AOI looks at, what kinds of defects can be checked during AOI, and the differences and benefits of 2D AOI vs 3D AOI. Chris also goes into some misconceptions regarding AOI and how you can design your CircuitHub to make it go through the AOI process more seamlessly.

Ep.12: An overview of bare PCB fabrication w/ Dave Wilcox

Even though we talk a lot about PCB assembly on this show, one aspect of the process still remains a bit of a mystery to Chris and Melissa - the ins and out of the PCB fabrication process. On this episode are joined by Dave Wilcox, a CAM engineer at CircuitHub who has been working with PCBs for 32 years. Dave gives us a 10,000 ft level overview of the PCB fab process, using a simple, standard 1.6mm thick, 2-layer board as an example and breaks it down into all the steps that have to take place in order to have a finished circuit board that is ready to be assembled:

Engineering/CAM

Drilling

Print Outer layers

Plating and Etching

Solder Mask

Surface finish - ENIG/HASL

Silkscreen

Routing

As always if you have any questions for us (or Dave), you can email us at contact@pickplacepodcast.com or tweet us @CircuitHub or @WAssembly.

Ep.11: Reflow Soldering

Welcome to another week! This episode Chris and Melissa discuss reflow soldering - the high volume soldering method that melts all of the solder at the same time and sets it to the circuit board. Even though it's a relatively simple process, it's a step that is really important to get right.

We go over the following:

-What is reflow soldering?

-Why is it important and why are we dedicating an episode to talking about it?

-Types of reflow ovens:

Vapor Phase

IR

Convection

-What is a Reflow Profile?

-Types of profiles:

Ramp, soak, spike

Ramp to spike

-What are the different stages of the profile?

-What aspects of the PCB design have an influence on how well an assembly will reflow?-----Why are the earlier process steps within surface mount assembly critical to an effective reflow soldering process?

-Any design tips to help ensure effect reflow solder?

A reminder that our giveaway for free assembly credit is still going on! For details on how you can claim $100 of CircuitHub assembly credit make sure to check out our last episode.

If you have any questions about the show, PCB assembly, or just want to say hi you can email us at contact@pickplacepodcast.com or tweet us @CircuitHub or @WAssembly. We'd love to hear from you!

Ep.10: How Joel Murphy went from visual artist to electronics design engineer

Welcome to our 10th episode of the podcast! Not only is this our 10th full episode, but we also have recently surpassed 1,000 episode downloads.

As a thank you to all our listeners we're giving away $100 of credit to ten people that can be used on PCB assembly of any future CircuitHub order.

Rules:

Send us a tweet (or a LinkedIn post if you don't have Twitter) letting us know something that you've enjoyed or learned from the show so far.

Make sure to mention both @CircuitHub and @WAssembly.

The credit will be rewarded to the first ten posts.

Credit can only be used towards assembly (not parts or bare boards).

On this episode we talk to Joel Murphy, an electro-mechanical designer and fabricator with 15 years of hands-on experience in the design of products and small scale production tooling. He's also a huge advocate for the Open Source Hardware movement, founder of Flywheel Lab, OpenBCI and more!

We had an awesome time chatting to Joel about how his work as a visual artist has enabled him to find a creative approach to problem solving in the electronics engineers and programming space that most engineers typically wouldn't think of.

Show notes:

Joel's background:

He started out making jewelry and small metal objects and later moved into making kinetic sculptures.

He started using different motivational forces for his sculptures including wind and gravity. Over time he started introducing more motorized things into his sculptures. His introduction into electronics began using relays to control different parts of the machine.

He became a physical computing professor at Parson's School of Design in New York.

We chat Joel's experience getting electronics made:

Flywheel Labs - "I do cool shit for other people"

Having the mindset of an artist rather than an engineer has helped him find workarounds to problems that people normally wouldn't even think of.

World Famous Electronics - maker of the Pulse Sensor

Joel's advocacy of the Open Source Hardware movement:

Being able to learn from open source designs has helped him become a better engineer.

Relationship between patents and oshw - how they work in cooperation or opposition

Je credits OSHW to allowing him to get where he is in this field

Open BCI - Open source brain computer interface, open source EEG machine

Disadvantages of OSHW

Joel also recently contributed to the MIT E-vent emergency ventilator project.

Regulations around building life saving devices.

We go into importance of communicating with your manufacturer special considerations and expectations you may have - real people who want to do a great job are behind building your stuff.

If you have questions about components call the distributor or part manufacturer directly, they want

Pet peeves:

Bad letter kerning

Footprints drawn in reverse on data sheets

If you'd like to get in contact with Joel or check out some of his work you can visit https://www.biomurph.com/

Want to get in touch with us? Email us at contact@pickplacepodcast.com or tweet us @CircuitHub or @WAssembly.

Ep.9: The PCB assembly inspection process

We think one of the best ways to understand what goes into PCB assembly is to speak to the experts themselves, those who spend day in and day out building your stuff!

On this week's episode we speak to Beata Laskowski, a quality control inspector at Worthington. Originally from Poland, Beata has been working in the electronics manufacturing industry for over thirteen years, seven and a half of which have been at Worthington. If you're a CircuitHub customer, it's possible you've had some back and forth communication with her answering questions on your order!

PCB assembly inspection is arguably one of the most important parts of assembly process as it ensures all components are placed and soldered correctly before your finished PCBs are shipped off to you.

We had a great time chatting with Beata about what her day looks like, the types of challenges she faces and how she makes sure that the boards we deliver are of top quality!

Beata hard at work!

Show Notes:

What is the first article process like and why is it such a crucial step?

We touch on how using CircuitHub has improved Beata's daily workflow.

What is the inspection process like, what do we look for, and how to we make sure that the quality is there?

Beata also performs a lot of rework on components. She explains some of the challenges she's faced.

What are the advantages of 3D AOI inspection over 2D AOI inspection?

Design recommendations:

If possible, use polarity markings on your boards that are still visible once parts have been placed.

If you don't have a color preference, choose green soldermask since they are the easiest to process.

If you have pictures of past pcbs you've had built elsewhere, include them with your order.

If you have any questions or feedback email us at contact@pickplacepodcast.com or tweet us @CircuitHub or @WAssembly!

Ep.8: How Loci Controls automates landfill methane gas collection

What happens to your bag of trash after you throw it in the dumpster? Most of us probably don't want to think in depth about this, but it's a problem that is constantly on the mind of this week's guest.

We had the pleasure of chatting with Matthew Laderer, Director of Engineering and Product Development at Loci Controls. Loci Controls' automated landfill gas collection platform increases landfill gas collection by 20% or more, ensures less methane is being released into the atmosphere, and reduces environmental, health, and safety risks.

We discuss what exactly Loci Controls does and why it's mission is so important, Matt's involvement with the company, his experience going from mechanical engineer to sourcing circuit boards, and more

Show notes:

Follow up question from previous episode: "You guys recommend to explicitly request filling those vias so the molten solder doesn't drain through it in the reflow stage. I was wondering why you don't do this by default for all vias with solder paste on them?"

More pcb design tips - circuithub.com/post/how-to-save-money-on-your-bext-pcb-project-part-2

Chris' pet peeve/design tip of the week: include the silkscreen outline of overhanging parts

For more information on Loci Controls you can visit: https://www.locicontrols.com/

If you ever have any questions or comments please don't hesitate to email us at info@pickplacepodcast.com or tweet us @CircuitHub or @WAssembly :)

Ep.7: Solder paste printing

On this week's episode we talk about something that at first glance might seem mundane, but is actually one of the most important steps and literally the foundation of pcb assembly: past printing. In fact, approximately 65% of all assembly defects come from this process. Chris breaks down all of the components that are a part of the often misunderstood process and provides some design tips on how to make it go smoother.

Show notes:

-Chris will be speaking at the upcoming virtual Altium Live conference. This year's event is free! https://www.altium.com/summit/

-We discuss what paste printing is and why it's so important.

Solder paste

-What is paste, what is it used for, and what are the different types of paste that can be used?

-Clean vs no clean paste

-Metal whiskering: https://en.wikipedia.org/wiki/Whisker_(metallurgy)

Jet printing vs stencil printing

-What is the difference between jet printing and stencil printing and what are the advantages and disadvantages of each?

Process

-What does the stencil printing process look like?

Stencils

-How are stencils made and what are they made of?

-http://www.stentech.com/Products/stencils

-https://www.youtube.com/watch?v=1gEcJvpinco

-https://nanoslic.com/nanoslic-coating-system/

Design tips:

-Use appropriately sized parts.

-Always avoid gang masking

-Tips to avoid via-in-pad issues

-Don't assume we'll use your data. Just leave it 1:1

-Be specific if you want paste on test points or battery contacts

-https://www.photostencil.com/technical-papers.php

Ep.6: The Open Source Ventilator Project with Dugan Karnazes and Nadim Conti

This week we are joined by Dugan Karnazes, CEO of design firm Velocity Research and Nadim Conti, System & Electronic Designer at the Italian National Institute for Nuclear Physics and Collaboration Member at CERN to talk about about their involvement with the Open Source Ventilator (OSV) Project. We discuss how COVID-19 disrupted their normal work lives, how OSV evolved, the importance of the project being open source, and more.

Official website for the Open Source Ventilator project: https://opensourceventilator.ie/

Assembly of the Open Source Ventilator boards by Worthington and CircuitHub: https://www.youtube.com/watch?v=pweALaGK-W0&t=3s

Nadim Conti:

Linkedin: https://www.linkedin.com/in/nadimconti/en

Website: www.nadimconti.com

Email : info@nadimconti.com

Dugan Karnazes:

https://www.linkedin.com/in/dugan-karnazes/

Website: velocityresearch.co

email: info@velocityresearch.co

OSV Specific email: covid19@velocityresearch.co

Twitter: @Velocity_RD

Instagram: @velocity_research

Facebook: @VelocityResearchGR

Ep.5: The pick and place assembly process

On this week's episode we talk about the pick and place assembly process (which also served as the inspiration for our show name) - the process of placing parts onto circuit boards using automated machines.

-We recap on how we've been adjusting in the factory amidst the continuing pandemic and how we're dealing with some of the growing pains as business starts to boom again.

-We discuss the steps after the parts are kitted that have to be done to get the board ready to be assembled:

The parts have to be loaded onto a feeder.

Loading an 8mm MyData feeder https://youtu.be/HU88ym0sdEQ

The feeders are placed in a magazine.

Mycronic feeders

Magazine

We briefly discuss the different types of feeders and magazines that are available.

On the Mycronic machines we use, the magazine is what advances the part in the pick and place machine.

MyData magazine advancement mechanism https://youtu.be/5ytCNuvdB2w

-We touch on the environmental impact of different types of equipment.

-Aside from tape and reel some parts come in tubes are trays and need to be loaded differently.

Mycronic stick feeder

-Why is set up one of the most time consuming steps in the whole manufacturing process?

-Once the parts are all loaded on to the machine, we describe the steps that have to be done in order to get it ready to run.

-We talk about the different types tools that are used to pick parts up and place them on the board and the technology that is used to make sure parts are being placed precisely and accurately.

-MyData machine in action https://youtu.be/B_bllEK55JU

-"Chip shooter" style pick and place machine: https://www.youtube.com/watch?v=nah4BQ9y8IY

-"Odd form" style pick and place machine: https://www.youtube.com/watch?v=EUxBMUS45Kg

-We talk things customers can do (and things we would prefer you to avoid) in order to make the pick and place process run smoother.

-On the next episode: We'll be speaking to Dugan and Nadim about their involvement with the Open Source Ventilator project.

Episode 4 - All about parts purchasing - part 2

In part 2 of our episode about parts purchasing with Brett and Magnus from Worthington, we talk about things we think customers should know about the process of purchasing parts and also the topic of parts consignments.

If you’re just tuning it, make sure to listen to part 1 first.

In part 1 we discussed what Magnus and Brett do for Worthington and CircuitHub, questions customers frequently ask us about parts and purchasing, and recommendations we have for customers.

This week we’re talking about things we think customers should know about the process of purchasing parts and also the topic of parts consignments.

Show notes

Attrition

-What is attrition and why is it required?

-Different reasons for attrition - reader attrition caused by loading the feeders vs attrition caused by the machine.

-How do we decide how much attrition to buy for each part?

Purchasing for production

-Purchasing parts for a prototype order vs production order?

-Parts discounts for multiple repeat production orders.

-What is the process of getting custom quotes for parts?

-How does quantity affect lead time?

-How are parts affected when scaling from prototype to production volume?

-What is involved from the part vendor’s perspective to get parts picked and delivered?

-Options for parts that are going out of stock that are critical components?

Consignments

-What scenarios do customers choose to have us consign parts rather than having us buy them?

-Best practices for sending parts to your manufacturer.

-Deadlines for sending consigned parts.

-Why don’t we like to accept fully consigned kits?

Ep. 3: All about parts purchasing - part 2

Intro

-This week we are joined by Brett and Magnus from Worthington to talk about parts and parts purchasing.

-Brett and Magnus give us a brief overview of what they do at Worthington and what they did before joining Worthington.

-We reflect on a twelve pound circuit board we are making and some of the challenges that come along with building something so big!

-Brett and Magnus discuss the differences in the part buying process for Worthington vs CircuitHub.

-How has COVID-19 affect parts purchasing and shipping?

Questions from customers

-Why is this out of stock?

-Why is my order held up? (What causes delays in delivering a product to a customer?)

-Why are these parts more expensive than when we previously bought them?

-We talk about how tariffs on parts get handled and billed (it’s not as simple as you might think).

-What is markup and why does it exist?

Recommendations to customers

-Use parts that are widely available in the supply chain.

-Speciy alternative parts that can be substituted whenever possible.

-Keep the lifecycle of the part in mind when designing your board - don’t use parts that are obsolete or nearing their EOL.

-Keep MOQs in mind.

-Small decisions early on can have a huge impact later on.

-Avoid using parts from hobbyist website - they are great for your personal projects but are not designed for professionally produced products.

-Be very careful (and sometimes suspicious) of buying parts from unauthorized distributors.

-Ask us if there’s anything different that they could do to improve the purchasing process?

Up next

We’ll continue the second half of the conversation in the next episode to discuss this things we wish customers knew and the whole subject of consignment.

Ep 2. The pcb assembly process

On this episode, Chris Denney gives us an overview of the assembly process, everything that happens after you place an order until when your boards are shipped.

Show outline:

We discuss the difference between placing an order at Worthington vs CircuitHub.

The three first steps happen in conjunction: Gerber data is submitted to begin board fab, the BOM is verified and purchased, the Gerber data and XY data is used to program the machines that will be assembling the boards.

These first three steps typically begin within the first 24 hours of submitting an order.

The board fab shop does a CAM process that verifies that your design is actually manufacturable.

The fab shop will send us an array file, which has the individualized design panelized that allows us to assemble the design automatically via machines.

The array data is used to program the stencil printer, pick and place machine, selective solder machine and AOI machine.

The BOM is purchased only from authorized distributors and customers send us any consigned parts.

After the parts come in they go through a kitting process.

Once the parts, bare boards and stencil are kitted they are released to the floor to be assembled.

The surface mount team loads the job onto the pick and place machine feeders.

Wet, tacky solder paste is printed onto the boards using the stencil.

The boards and parts are loaded onto the pick and place machine where the vacuum tools on the machine will suck up the parts and place them onto the machine.

Solid solder joints are created by running the board panels through a reflow oven.

The boards then go through AOI (automated optical inspection) which determines whether the parts are there and if they are placed correctly.

If a board is double sided it repeats the whole process.

Through hole parts gets inserted by hand and soldered using a selective solder machine or by hand.

The boards are inspected by humans.

The boards are de-panelized into individual boards.

The boards are wrapped in ESD safe bubble wrap and ESD shielded bags and then shipped.

We've shipped to every continent except Antarctica!

You finally get your boards!

What topics are listeners most interested in learning more about?

On the next episode we'll be talking to Brett from Worthington to talk about part purchasing.

E1: Get to know the show

Join hosts Chris Denney and Melissa Hough as they discuss their involvement with CircuitHub and Worthington. Find out what you can expect to learn on Pick, Place, Podcast.

Welcome to our new show, the Pick, Place, Podcast! On today’s intro episode, join hosts Chris Denney and Melissa Hough as they discuss their involvement with CircuitHub and Worthington. Find out what you can expect to learn on the Pick, Place, Podcast.